Advancements in Exhaust Design Result in Significantly Fewer Maintenance Issues

For food or beverage plant managers, ineffective exhaust of cooking or freezing air can be a major headache – and a costly one, too. Fortunately, advancements in exhaust technologies are contributing to a lower lifecycle cost and easier maintenance for exhaust equipment, while also producing extremely effective exhaust of processed air.

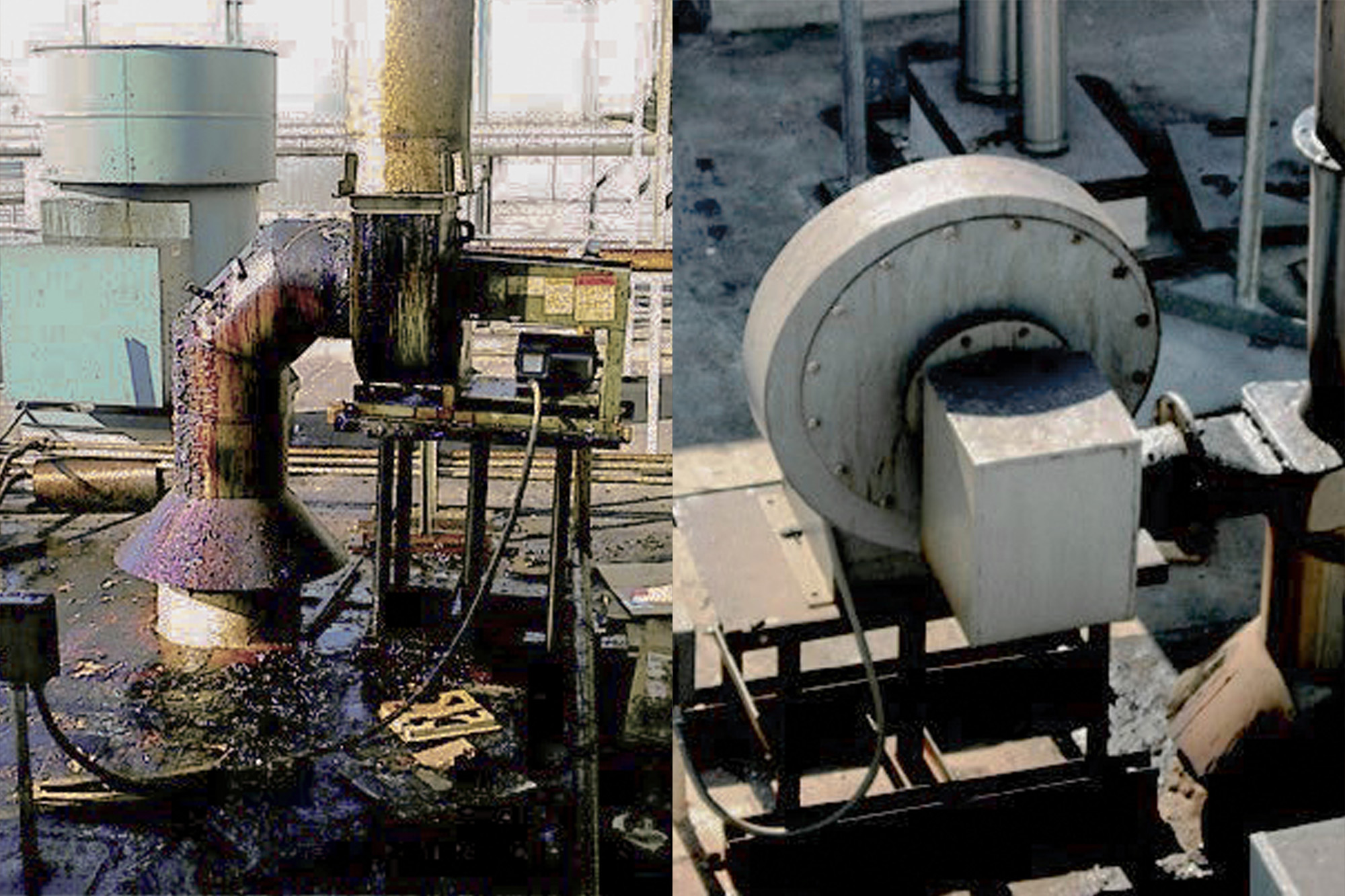

For instance, a Venturi-style rooftop exhauster includes several design features that result in improved performance and reliability. The system’s pressure blower is located adjacent to the exhaust duct. The blower draws ambient air and injects it at high velocity and pressure through a plenum chamber controlled by a nozzle in the Venturi. This process of channeling the air through a restricted space to accelerate the air is known as the Venturi effect. This approach to exhaust causes the air to flow upstream from the Venturi.

By keeping the blower mechanism separate from the air that needs to be exhausted, it prevents contaminants, such as grease particulates, from adhering to fan impellers and throwing the equipment out of balance. Additionally, the Venturi-style exhaust system duct can be thoroughly cleaned without risk of damaging the blower. This arrangement also makes it easy to access the blower for routine maintenance.

The Venturi-powered exhaust system from Quickdraft offers several additional benefits beyond the advanced airflow. The Quickdraft Venturi Exhauster’s blower is housed in an enclosure to protect it from weather for increased reliability. The blower is constructed of carbon steel for 24/7 reliable performance.

To prevent exhaust contaminants from fouling the rooftop, Quickdraft provides two solutions. Velocity Reduction Chambers prevent material carryover onto the roof. Demister Exhaust Filtration Systems from Quickdraft filter grease, oil and other contaminants from the exhaust air stream to prevent grease and oil from accumulating on the roof. These solutions protect other roof-mounted equipment, eliminate the expense of roof cleaning, extend the service life of the roof and help prevent pest problems. The Demister Exhaust Filtration System also includes a water recirculation tank for reduced water consumption and lower operating costs.

Quickdraft Venturi Exhaust and Exhaust Filtration Systems provide superior exhaust for fryers, ovens, microwave ovens, blanchers, char-markers, baking applications, mixers, caustic chemicals, acids, high-temperature applications and freezing tunnels. The system is particularly suited for cryogenic exhaust. Because vapors do not contact any moving parts, ice will not build up on the impeller. The risk of fan failure and motor replacement resulting from wheel seizure are eliminated. The system also minimizes the need for expensive conditioned air used to prevent in-line fan freezing.

The experts at Fluid Flow have been helping food and beverage plants improve their operations through cost-effective processing solutions for over 50 years. To learn more about how a Venturi-powered exhaust system will safeguard your rooftop and provide reliable performance, please download the Quickdraft brochure or contact a Fluid Flow representative for more information.